Visit our seminars & become a Transformer in your company!

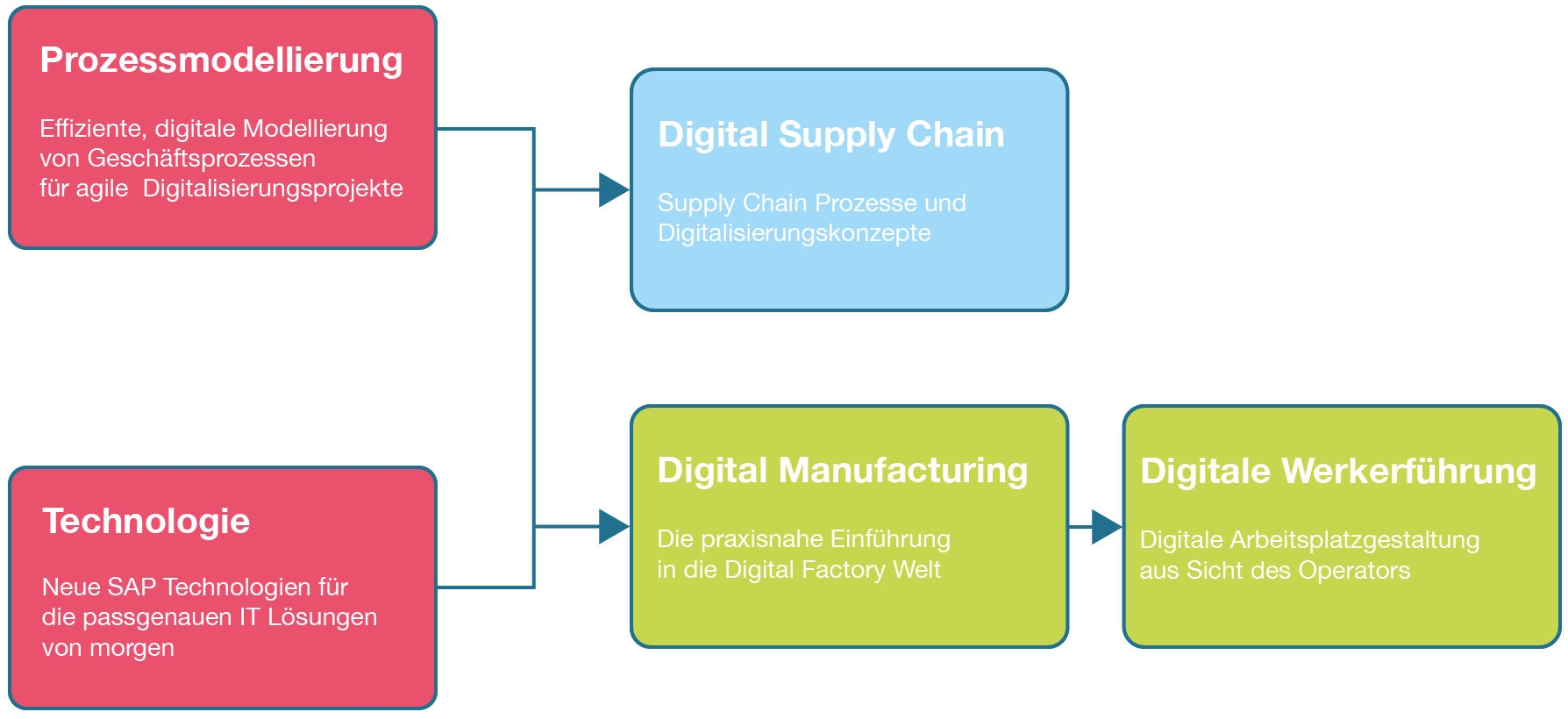

Learning Journey Digital Transformer

Digital transformation is teamwork. It needs clear goals, documented processes and reliable technology – and more than ever, it needs well-trained, motivated people.

Our training portfolio provides the practical knowledge required to implement successful digitalization projects in the manufacturing industry.

This enables you to give your team the tools they need to be successful before embarking on small or large digitalization tasks. The concentrated experience from more than 300 projects in over 100 industrial companies, numerous case studies and a lot of tips & tricks is the basis of these seminars. As external consultants, we know exactly how we can best prepare you and your team to:

- Design processes efficiently

- Bring your software development and architects up to date technologically

- Implement modern supply chain concepts digitally

- Make the digital factory a reality

Attention! Our seminars have a lasting effect!

Our presence seminars

Digital Manufacturing

with Fraunhofer Austria

Next Date: 09.-11.07., 2024, Vienna

Language: German

Digital Manufacturing

with Octotronic

Next Date:

10.-12.06.2024, Switzerland

Language: German

Digital Supply Chain

with inloop

Next Date: 05.14.-16., 2024, Vienna

Language: English

Process modeling

available on request

TECH-Architekt

available on request

Digital Operator Guidance

Next dates: Summer and fall 2024

Further information and registration will follow shortly!

Webinars

Integrated Personnel Resource Planning

March 6, 2024, 10:00-11:00

Language: English

Mastering SAP Logistics

16. April 2024, 14:00-15:00

Language: English

About concircle academy

The concircle Academy offers effective and practical programmes to train specialists for the digitalization of business processes. The aim of the Academy is to enable companies and their employees to successfully plan and implement digitalization projects.

The training programs are designed together with partners using the experience gained from a large number of consulting and implementation projects within the concircle group. In addition to up-to-date specialist knowledge, the focus is on immediate feasibility in practice. All trainers have many years of practical experience.

Take advantage of the concircle academy’s training opportunities and lay the foundations for the successful digitalization of your company!

Let us put together a customized seminar for you!

- Would you like to book the Learning Journey Digital Transformer as a package including all seminars with a discount for your company?

- Would you like us to address your specific needs in a customized seminar?

Contact us and let us advise you!

Contact

Petra Kauth

Marketing

Do you need more information about our events and activities? We are happy to provide you with further information.