Digital Supply Chain:

IBP Implementation Best Practices

A training program of the concircle Academy

Attend our seminar & become a transformer in your company!

Next Date

May 14-16, Vienna

The language of the seminar is English

Why this course

Integrated Business Planning (IBP) and Sales and Operations Planning (S&OP) are integral parts of business management with a cross-functional focus ranging from finance through IT, sales & marketing to operations. S&OP is a comprehensive process that lies at the core of a successful supply chain management. This course presents tools to empower businesses and IT organizations to effectively implement Sales & Operations Planning (S&OP) or Integrated Business Planning (IBP).

Who this workshop is for

- Supply chain managers & decision makers

- Executives & group leaders

- Users looking for best practices for their IBP or S&OP initiative

Your personal benefit

You will learn…

- everything about the typical flow, participants and evaluation criteria of S&OP/IBP projects

- more about industry-specific S&OP/IBP project examples

- how to incorporate trends that are linked to S&OP/IBP into your supply chain management

In addition, each participating company has the opportunity to request an individual, 1-hour meeting. The number of meetings is limited and will be allocated on a first come first served basis. Do not hesitate and register today – write us a short message in the registration form (“Your message” field) if you are interested in the individual meeting.

MODULE 1 (Registration from 9:00 am, workshop 9:30 am – 4:00 pm)

Project Preparation & Timeline – Scoping, Best Practices

In this module, we will show how a typical S&OP or IBP project starts. We will discuss the different states of supply chain planning processes, planning KPIs, visions for integrating planning and execution, and linking processes from different departments. As there are different methodologies on the market, the intention is to present some best practice approaches depending on the industry, e.g. CPG, Mill, Life Science.

The following topics will be discussed:

- Why do you need a supply chain maturity assessment?

- What are the most common bottlenecks in the supply chain?

- How can you get your supply chain goals from A to B?

- Project preparation and roadmap of business and IT

- Industry-specific best practice solutions for the digital supply chain

MODULE 2 (9:00 am – 4:00 pm)

IT Implementation & Solutions

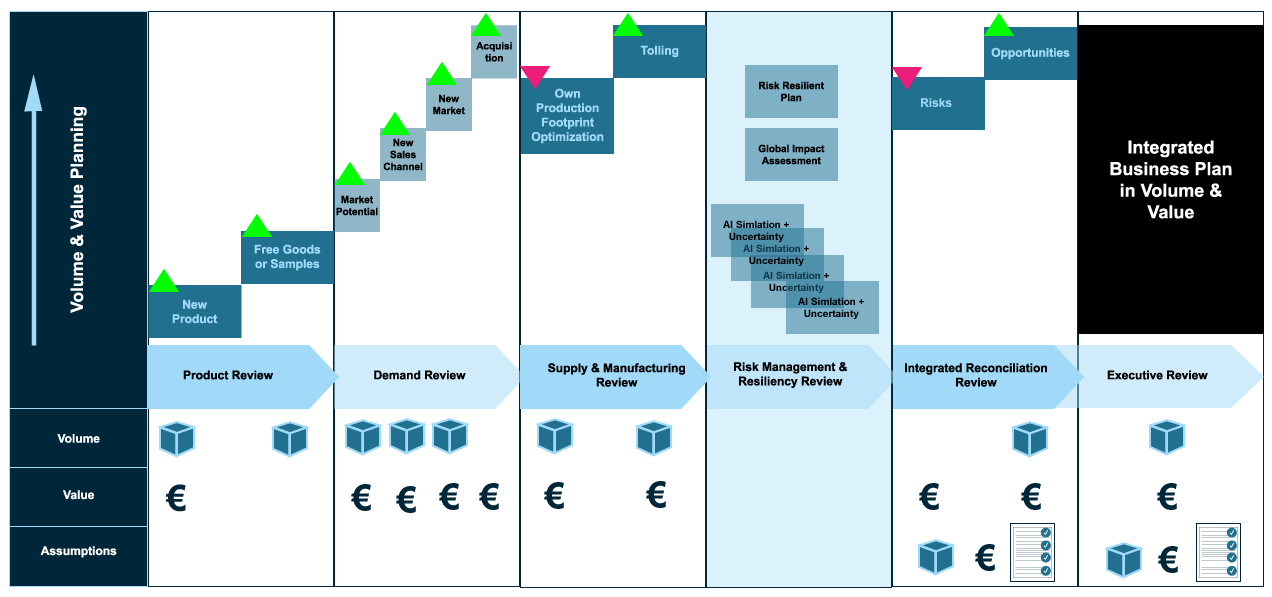

In the second module, you will learn how the solutions are implemented. In most cases, this involves the implementation of both business and IT processes. A business process implementation means that some changes are made to the current way of working, resulting in a more efficient one. An IT process implementation, on the other hand, means a new system that is designed to improve the current process. We will cover:

- Implementation of tailor-made IT tools and improvement / adaptation of current processes

- Hands-on presentation of various supply chain requirements

- Demonstration of IBP and S&OP planning tools in use

Picture: A typical IBP process

MODULE 3 (9:00 am – 2:00 pm; wrap-up until 4:00 pm)

Roll-out and Continuous Improvement

The last module covers the preparation of the change management process and its implementation options. A strategy for continuous improvement has to be prepared in order to achieve the company’s long-term goals. As new challenges in the supply chain can arise at any time, companies and IT departments should be able to draw up concrete plans for overcoming them. The following topics are addressed:

- Change management & implementation support

- Strategy for continuous imprvement

- Corporate communication including timeline

- Training plan and creation of a manual

Presenters

Rodrigo Villanueva

Digital Process Architect

Rodrigo Jr. has many years of experience in supply chain planning. He knows IBP like no other and enriches the Digital Supply Chain team with his extensive experience. His focus is on the pharmaceutical, life sciences and consumer goods industries.

Matthias Payer

Project Manager

With +15 years of experience in logistics and supply chain management, Matthias has a broad consulting focus and extensive industry reach. Specialized on supply chain planning, he joins companies to successfully implement IBP processes, organizational structure and change management.

Gregor Gluttig

Managing Partner

With 20+ years of supply chain management experience, Gregor has led intricate projects within international enterprises. Through the design and implementation of IBP and S&OP, he has driven tangible results such as working capital reduction and lead time optimization, while developing both resistant and sustainable supply chains.

Venue

twelve

myhive am Wienerberg

Wienerbergstraße 11

1100 Wien, Österreich

Partner

inloop thinks ahead – combining its know-how with supply chain strategy, circular economy, logistics, and digitalisation. inloop stands for cohesion in resilient and sustainable supply chains and puts the spotlight on value chains from procurement to end consumption and beyond. Our inloop consulting team works in a variety of industries, sectors and disciplines of supply chain management. Inventory optimisation, integrated business planning, IT strategy and selection as well as strategic network development are among the topics we are passionate about applying our expertise and experience to.

concircle is a technology consulting and software development company headquartered in Vienna, operating mainly in the DACH and CEE regions. The company specializes in the development of tailor-made software solutions for companies of all sizes, from start-ups to large corporations. concircle’s team of experts focuses on developing high-quality, innovative solutions using the latest technologies and methods. concircle has made a name for itself as a reliable partner for companies looking for secure and effective technology solutions.