Digital

Manufacturing

A training program of the concircle Academy

Next date

July 9-11, 2024

Attend our seminar & become a transformer in your company!

Next date

July 9-11, 2024, Vienna

Why this program and what is your advantage

This effective and practical program trains TRANSFORMERS for digital manufacturing who have a good understanding of IT landscapes and digitalization processes, know how IT and processes can be harmonized and have insights into how efficient digital processes work end-to-end in production. They also learn which challenges and special features need to be considered in digital transformation projects and how to successfully shape a digital transformation in production.

Your personal benefit

After this course…

- you will become a manufacturing transformer in your company

- you will know what is important in digitalization projects

- you will have the necessary skills to make a powerful contribution to digitalization projects

- you know how digitalization projects should be organized, structured and designed

- you understand a digital factory end-to-end

- you are qualified to coach and motivate your employees in a targeted manner

MODULE 1

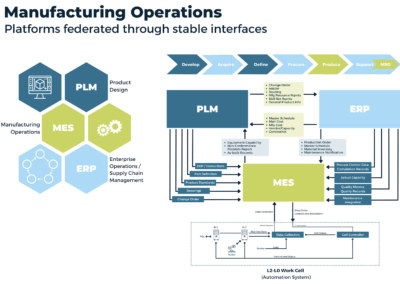

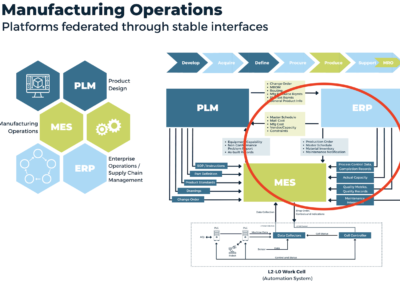

Business value, architecture, IT landscape and process

On this day, the transformers learn about different forms of IT architectures and IT landscapes in a manufacturing company as well as different system implementation strategies. They will also learn how to quantify, evaluate and present the added value in digitalization projects as well as methods for effective change management.

Overview – what is answered

- What does “digital manufacturing” mean?

- In-depth understanding of IT landscapes and relevant industrial information systems and their modules (ERP, MES, etc.)

- A digital execution of production through MES system (based on ISA S95 Standard/VDA)

- Production processes, including production planning and scheduling

- Quality measures

- Maintenance measures

- Inventory measures

- Process modeling and efficient communication with external and internal consultants

Processes – WHICH PROCESSES ARE CONSIDERED?

- All processes and organizational units in the company that are relevant to production

- An end-to-end example process in discrete manufacturing

- Modeling according to BPMN Excursion with Cawemo and example process from customer order to delivery

IT systems

- Modern IT architectures and systems

- Business requirements for the IT infrastructure

- Cloud, on-premise and hybrid architectures

- Modern machine connection technologies

Project and change management

- Best practice approach for digitization projects as well as challenges and risks

- Agile project management

- Requirements for the organization and project members

MODULE 2

Industrial AI applications

On this day, the transformers will learn how AI can increase productivity in production. They will learn which challenges AI addresses, which data is required and how it is prepared for use in AI models. The selection and testing of suitable AI models and their implementation in production systems is also covered. An insight into data management and best practices for the introduction of AI solutions is provided.

Overview – what is answered

- How can artificial intelligence sustainably increase productivity? Step-by-step

- What challenges can be addressed by AI in production?

- What data is needed to address challenges through AI?

- How must data be prepared so that it can be used in an AI model?

- Which AI models are available to address challenges?

- How can I check whether the AI is suitable?

- How can AI be successfully implemented in production systems?

Processes – WHICH PROCESSES ARE CONSIDERED?

- Cross Industry Standard Process for Data Mining: theory and practice

- AI lifecycle in the production system through the DevOps process

IT Systems

- Databases, structures and pipelines

- Infrastructure for AI systems

Project and change management:

- Best practice for the introduction of an AI solution in the area of maintenance

- Ethical considerations and acceptance: Responsible AI

MODULE 3 (Pilot Factory)

Paperless production planning and execution – digital factory in practice

On this day, the transformers will learn in practice how digital production planning, control and execution are carried out end-to-end and what connections exist between these processes. They will also learn about the role of relevant industrial information systems and their interfaces and understand how to implement IT landscapes for production. At the end of the day, the transformers will know how to make production 100% paperless.

Overview – what is answered

- What is a modern detailed planning process?

- What is modern workforce scheduling like?

- Material and equipment-optimized production

- Sales order and stock order production strategy

- What does digital production execution look like using the example of SAP S4 HANA and SAP DMC?

- Digital intralogistics process and interaction with production processes

- Digital maintenance

- Digital quality assurance in production

- The critical role of master data

Processes – WHICH PROCESSES ARE CONSIDERED?

- Production planning process

- Production execution

IT systems

- Relevant modules of the ERP system

- Production execution system (MES)

- Transportation and warehouse management system

Project and change management

Best practice approach for implementing an integrated IT landscape for digital production

Tools and Software

Transformers like YOU!

Speakers

DI Dr. Farhang Akhavei

Farhang has many years of research experience in the fields of production and manufacturing control, automation technology and product lifecycle management and supports our team in the implementation of innovative MES projects.

Dipl.-Ing. Dr. Konrad Pfadenhauer

Konrad is a passionate consultant for MES and production-related processes across many industries. He has already been able to accompany many international customers on their individual digitalization path in production.

Dipl.-Ing.(FH) Sandra Wildeis

Sandra is an independent organizational developer, trainer and coach. Thanks to her many years of experience in industry, she is familiar with the challenges, potentials and paths in transformation projects from a holistic perspective in various roles – from production planner to production manager and HR manager – and as a lecturer and consultant.

Dipl.-Ing. Philipp Besinger

Philipp Besinger has been working at Fraunhofer Austria in the Digitalization and Competence Management Group since 2021. During his studies of industrial engineering at the Vienna University of Technology, he laid the foundation for his specialization in digitalization and AI applications in the production sector. At Fraunhofer Austria, he has established himself as an expert in the design, implementation and integration of cognitive assistance systems in production. With an interest in innovative approaches, he deals with methods such as knowledge graphs or large language models in order to use them profitably in industrial processes.

Benedikt Fuchs

Benedikt Fuchs has been working at Fraunhofer Austria in the field of work design and digitalization since January 2020, where he played a key role in the development of the topics “Industrial Digitalization Strategies” and “Data- and Trend-based Competence Management” as well as the establishment of corresponding research groups. As part of industrial contract research, he led numerous projects, including a multi-year series of projects to develop an AI-based learning assistance system to support employees in the production environment. Since 2023, he has headed the Digitalization and Competence Management group, in which he and his team develop human-centered solutions to strengthen operational knowledge management based on natural language processing methods.

concircle Academy Registration

July 9-11, 2024 in Vienna, Austria

Register now to learn from experts and gain valuable insights into digital manufacturing. We look forward to your participation in our three-day seminar!

Petra Kauth

Marketing

Do you need more information about our events and functions? We will be happy to provide you with further information.

Thank you very much!

Your registration was successful

Grants

Location

twelve

myhive am Wienerberg

Wienerbergstraße 11

1100 Wien, Österreich

Pilotfabrik

Pilotfabrik, tz1

Seestadtstraße 27/3,

1220 Wien, Österreich

Partner

Fraunhofer Austria Research GmbH was founded at the end of 2008 as a foreign subsidiary of the Fraunhofer-Gesellschaft. In the business units “Factory Planning and Production Management”, “Logistics and Supply Chain Management”, and “Work Design and Digitalization” in Vienna, in the business unit “Visual Computing” in Graz and the two Fraunhofer Innovation Centers “Digital Transformation of Industry” in Wattens and “Digitalization and Artificial Intelligence KI4LIFE” in Klagenfurt, around 70 scientists are currently working on application-oriented solutions for the benefit of the economy and society. Research for practical application is the central task of the Fraunhofer institutes.

concircle is a technology consulting and software development company headquartered in Vienna, operating mainly in the DACH and CEE regions. The company specializes in the development of tailor-made software solutions for companies of all sizes, from start-ups to large corporations. concircle’s team of experts focuses on developing high-quality, innovative solutions using the latest technologies and methods. concircle has made a name for itself as a reliable partner for companies looking for secure and effective technology solutions.