SAP MPS: Transparent production planning with SAP S/4HANA

Due to increased complexity in supply chains creating a finite and feasible production schedule is becoming ever more of a challenge. Classic MRP calculations do not take into account many of the constraints that apply in procurement and production and there require a lot of manual effort from the planner. The lack of visibility results in non-optimal solutions, having the possibility to simulate different scenarios would help to find the best scenario but this is often very difficult.

SAP S/4HANA Manufacturing for Planning and Scheduling (formally known as PP/DS) closes this gap and provides advanced tools for both rough-cut planning and detailed scheduling. MPS offers features like Pegging, which gives planners transparency on how demands are covered. Real-time alerts help the planner to direct attention to potential issues in the production network. The extensive heuristic framework gives planners a powerful toolkit to resolve problems flexibly depending on the situation.

Functions

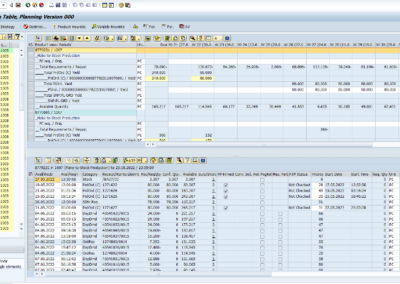

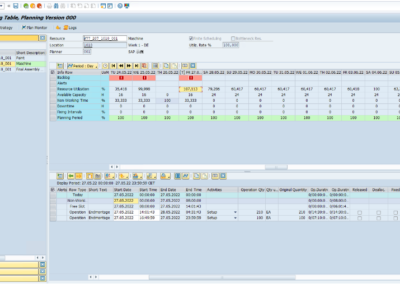

Rough-Cut Planning

Create a fully integrated production and procurement plan for the mid-term horizon and gain an overview of potential capacity overloads and material availability issues

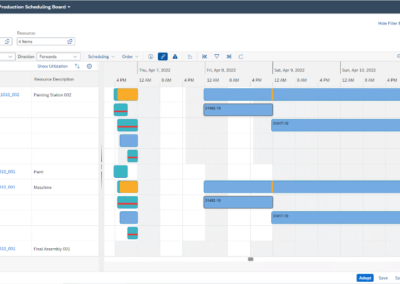

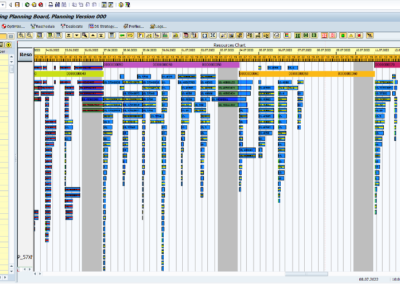

Detailed Scheduling

Create a finite schedule on bottleneck resources considering material availability. Utilize industry-specific functions like block or campaign planning to further optimize and stabilize your production schedule

Synchronized Planning

Integrate your rough-cut plan from SAP IBP and hand it over to SAP MPS to create a finite production plan. These results will be integrated back to IBP and are used to confirm sales orders or for the detailed planning of stock transfers

Martin Baldauf

Product Manager SAP S/4HANA MPS

Do you have questions about this solution, please contact me for a non-binding discussion! +43 676 7145003