Now, the second phase of the SAP ME implementation has also been completed at the Austrian TU Vienna Pilot Factory Industry 4.0.

In the assembly line, which is equipped according to the latest technology standards, the 3D printer developed by the TU Vienna will be assembled from now on. Here, the entire product cycle is mapped on the store floor in a self-contained logistical concept from the customer order through planning to the production process. Embedded in a homogeneous, multilayer SAP IT landscape with fully horizontally and vertically integrated system levels, a continuous flow of information is implemented within and between the various system levels.

With the additional innovative highlights such as:

- IoT platform and cloud connectivity

- Order planning with conOS

- Virtual Reality Glasses

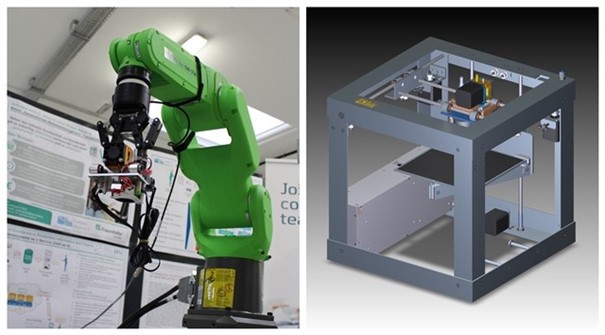

- Human Robot Collaboration

- AGV and robot connection

- 3D Simulations

- Intelligent User Interfaces

- End-to-end traceability and archiving of all traceability data

- Prognoses and Forecasting

viewers are given a unique insight into the entire production process from the perspective of the end-user.

Digital Production Cell with SAP ME:

Digital Assembly with SAP ME: