Feasibility analysis (POC)

- Experience SAP DM live with your own data

- System deployment + 10 days consulting by concircle

- Lead time: 1.5 months

Safe Passage Analyse

- SAP DM Readiness Check

- Added value analysis in comparison to existing MES (SAP / non-SAP)

- Conversion concept

- Lead time: 1 month

Digital Factory Plug & Play for SMEs

- SAP DM implementation with relevant standard functions

- For SMEs with up to 300 employees

- For one plant

- Lead time: 6 months

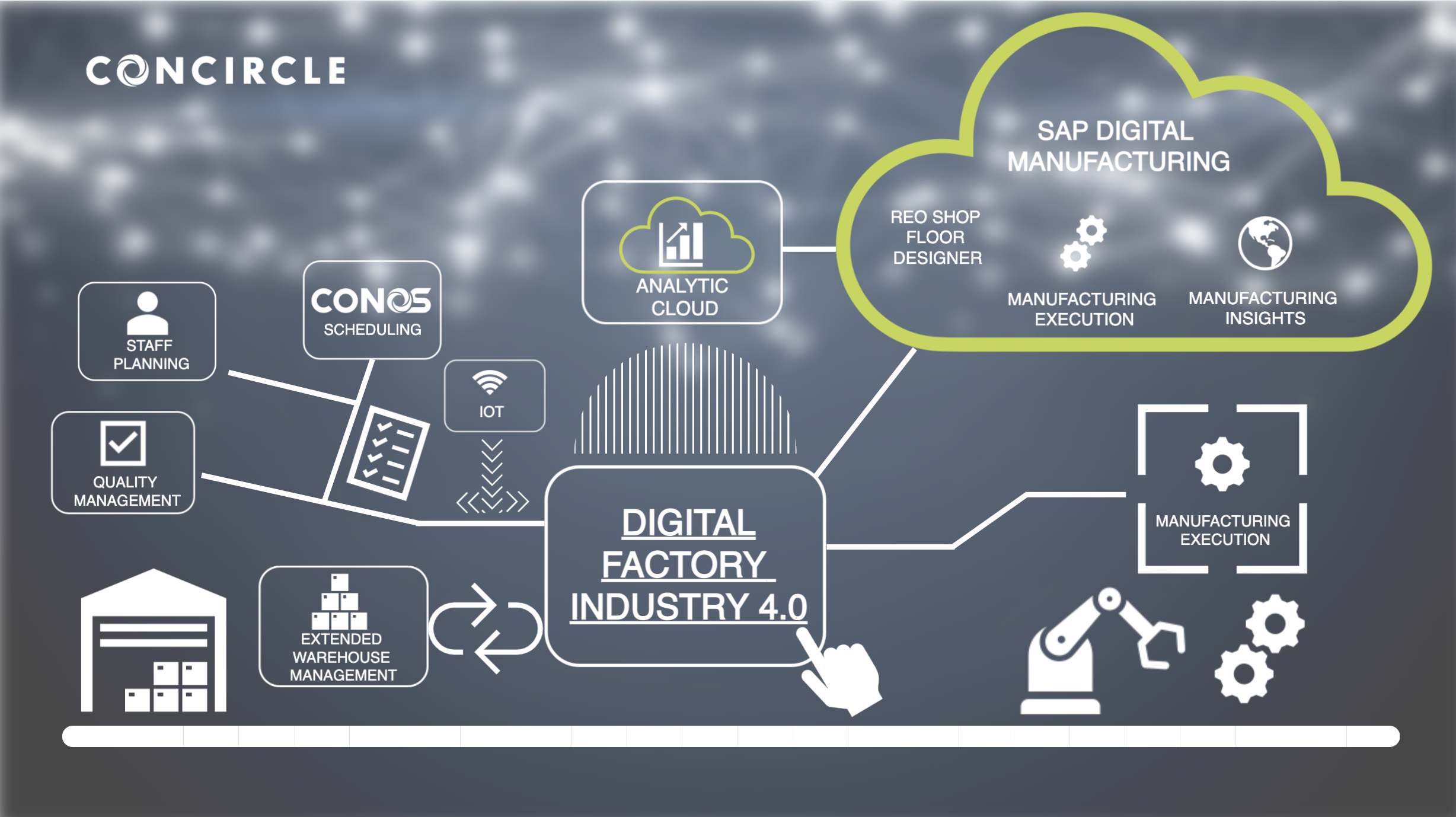

SAP DM: Digital Manufacturing

SAP Digital Manufacturing (SAP DM) is a central, flexible and scalable standalone MES system in the cloud. SAP DM is a standalone MES System and can be integrated directly with SAP S/4HANA as well as with the existing SAP ERP ECC.

SAP Cloud-based MES system is a “Software-as-a-Service” solution approach for Manufacturing and offers besides strong scalability numerous standard features that assure 100% transparency and traceability in manufacturing. The following are among the other benefits of SAP DM:

- Application of further cloud services such as real-time analytics and machine learning to better understand and optimize processes

- 100% end-to-end visibility of all manufacturing processes across sites

- Fast adaptation to requirements due to the scalability of the cloud-based MES solution

- No investment in hardware as well as infrastructure and therefore outsourcing of high-maintenance decentralized server installations

- Assurance of data and system availability through professional support of the central servers

- Real-time reports on different vertical levels

- Integrated planning, execution and reporting functions

- Orchestration of production processes in unified and hybrid system landscapes

SAP DM functions:

SAP Digital Manufacturing (SAP DM)

- High-performance MES system in the cloud without the need for own hardware infrastructure

- Suitable for discrete production and process industry

- Modern User Interfaces

- Production and detailed planning (REO)

- KPI Monitoring and Insight System

Further functions

- Traceability / Lot size 1 management

- Production order management with SAP PP integration

- Material Management with SAP MM Integration

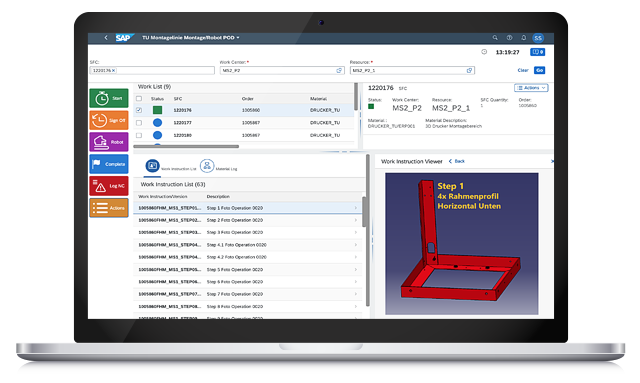

- Work instructions

- QM characteristics recording incl. SAP QM integration

- Tool management

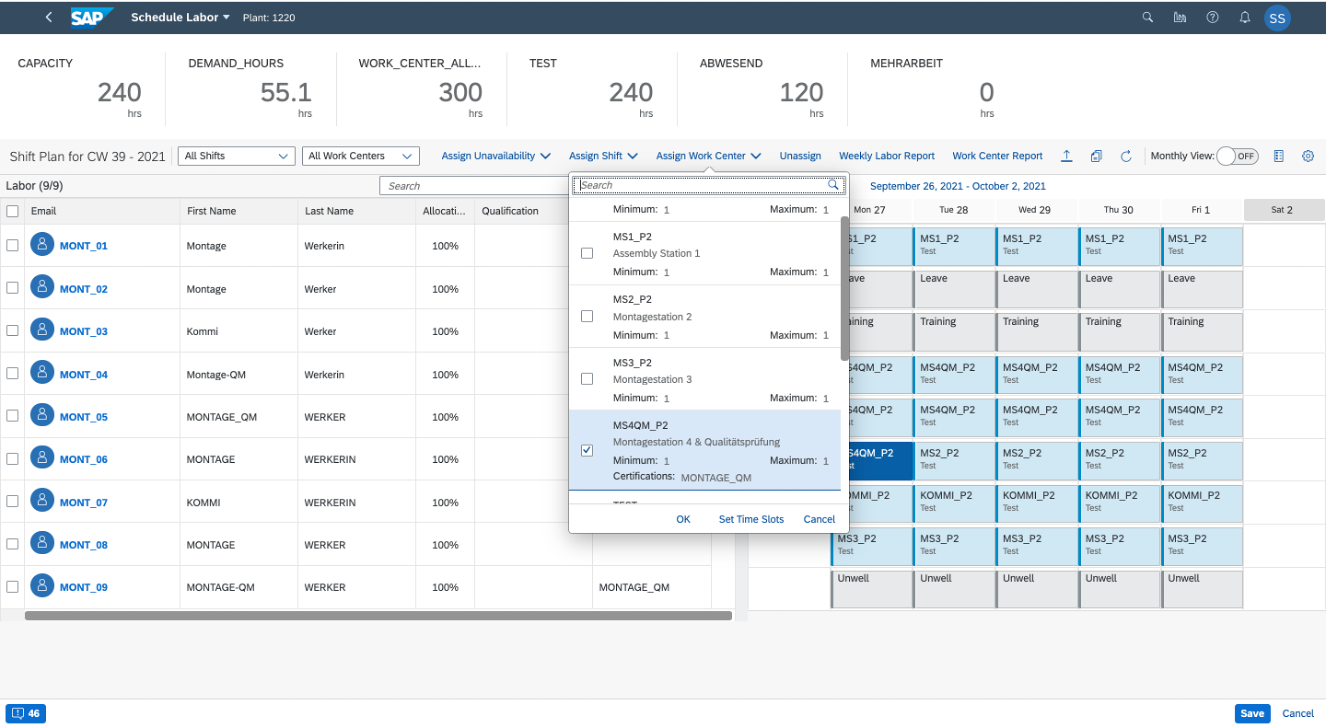

- User and qualification management

- Warehouse Integration (EWM)

Module:

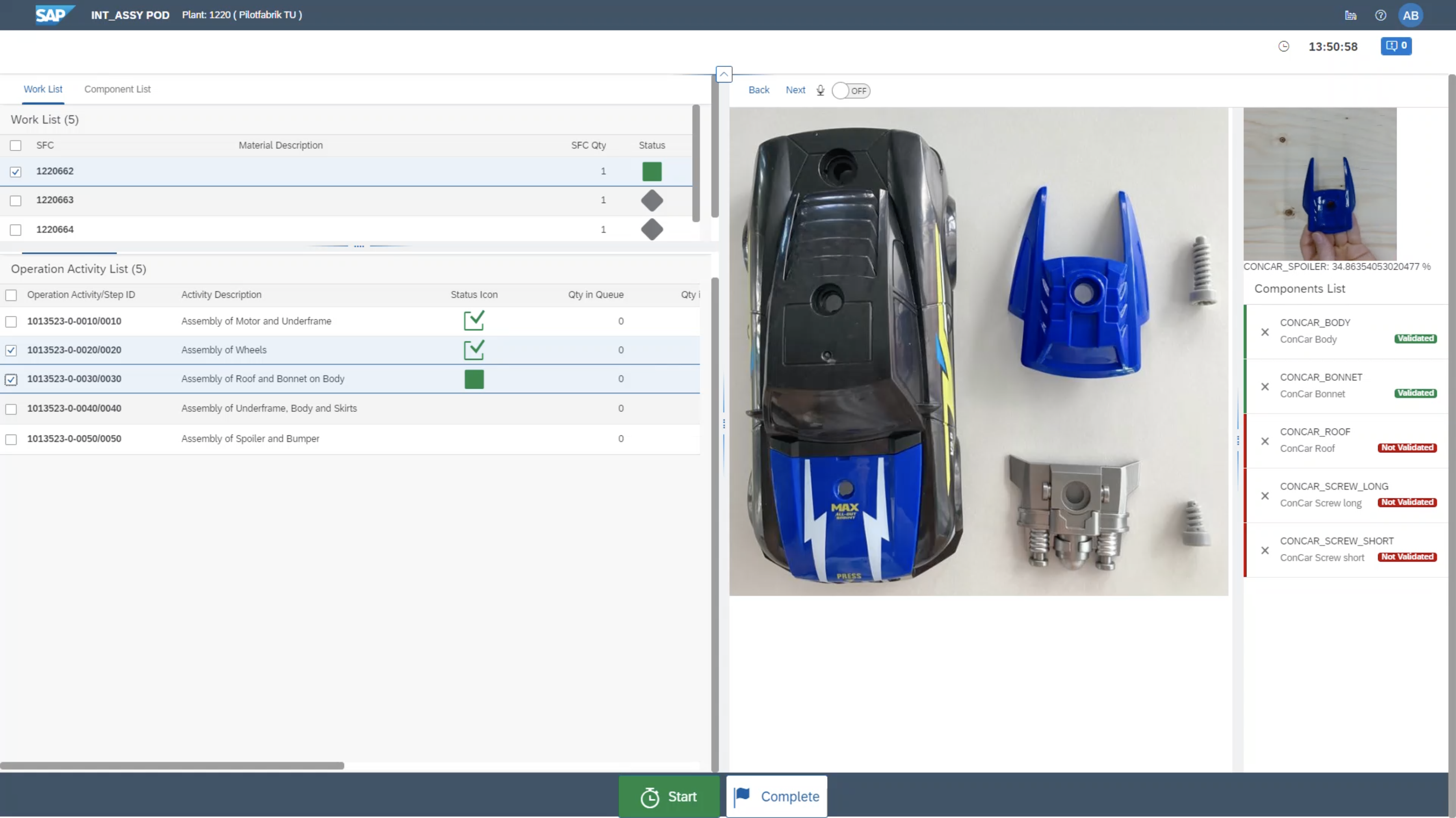

SAP DMe Execution

- Central production control system on the store floor

- Planning and control of orders, resources, personnel, work steps and work equipment in production

- Ergonomic, easy to understand and graphical user interfaces

- Error prevention in production and assembly

- Provides MES solutions for both discrete manufacturing and process industries

SAP DMi Insights

- Central and data-based performance management system

- End-to-end transparency in production at various levels from the individual machine to the entire plant

- Provides KPIs and visualizes the real-time information via a dashboard function

- Can be connected in various hybrid architectures and also consolidate data from other systems such as SAP S/4HANA, SAP ME on-premise or non-SAP systems

SAP DMn Manufacturing Network

- Ensures a comprehensive flow of information and optimizes the orchestration of processes between the company and its customers, suppliers and service providers

- By integrating with SAP S/4HANA, this module can enable integration not only at the production process level, but also at the procurement level to make integrative processes such as quality assurance much more efficient

Customer-specific enhancements in SAP DM

Limited flexibility for custom extensions has been one of the main criticisms of cloud-based applications. With SAP DM Cloud Architecture, this point of criticism is now invalidated, as the modern Java and Java Script extension modules allow custom extensions to be implemented directly in the cloud and made scalable. For example, the concircle team has implemented the following specific extensions in SAP DM in recent years:

-

- conDNC: Integrated machine program and tool management module

- conLABOR: Precise personnel and machine time recording module

- BOMviewer: Flexible representation of complex parts list structures

- WEBviewer: Flexible POD plug in for displaying various standard and custom data such as logged in employees, long texts, CNC programs, workstation status, etc.)

- Shift Leader Dashboard: Flexible display of production data for team leaders and managers in production control

- Operation of the user interface with voice control

- Operation of the user interface with gesture control

- BOM control in an assembly process with image recognition

- Custom plug-in for video-based work instructions

A successful SAP DM implementation requires an implementation partner who not only uses IT technologies innovatively but also fully understands the production processes. With years of experience and countless successful projects, concircle not only has industry and process-specific knowledge but is also able to map the customer’s needs and requirements to the appropriate SAP Cloud systems. Many years of cloud expertise in a public and private cloud, conception and implementation of hybrid approaches such as on-premise/cloud or SAP/Microsoft Azure architectures as well as many successful regional or global rollouts distinguish concircle as a competent partner that accompanies industrial companies on their way to the cloud.

Experience SAP DM Live at the TU Vienna Pilot Factory for Industry 4.0

Through a full implementation of SAP DM in the TU Vienna pilot factory for Industry 4.0, the concircle team was able to evaluate the DM functionality in detail and directly compare the SAP SaaS solution DM with the classic on-premise MES SAP ME. The close cooperation between concircle and the TU Vienna Pilot Factory for Industry 4.0 as well as the full integration of SAP DM into the production system offers the unique opportunity to experience an integrated IT landscape based on SAP DM and S4 HANA System live in one of the most modern Smart Factories in Austria. The demo presentations can be held both physically at the TU Vienna Pilot Factory for Industry 4.0 and online on request. Sounds interesting? Contact us for a demo!

FAQ

What does SAP DM stand for?

SAP DM stands for SAP Digital Manufacturing and is a product of SAP, a leading global provider of business process control software.

What is SAP DM?

SAP Digital Manufacturing is a cloud-based manufacturing execution system (MES) and provides a flexible, scalable solution for both discrete and process industries.

What is SAP DM used for?

SAP Digital Manufacturing supports production planning and control and, as a manufacturing execution system, represents a digital image of production.

What is the difference between SAP ME and SAP DM?

SAP Digital Manufacturing offers comparable functions to SAP Manufacturing Execution (SAP ME) and SAP Manufacturing Integration & Intelligence (SAP MII) but can draw on more extensive analysis and reporting functions, as well as utilise the full potential and advantages of the cloud.

Why is SAP DM important?

With SAP Digital Manufacturing, the Software-as-a-Service (SaaS) business model is being pursued and optimisation algorithms or “Artificial Intelligence” and Machine Learning (AI & ML) are increasingly being used, which is why SAP DM represents an important step towards Industry 4.0.

What are the benefits of SAP DM?

SAP Digital Manufacturing can score points above all with the advantages of the cloud, such as high availability of data and quickly scalable system resources, as well as a central instance for the orchestration of production processes.

Farhang Akhavei

Team Lead Digital Manufacturing Consulting

Do you have questions about this solution, please contact me for a non-binding discussion!

+43 676 6209480